B

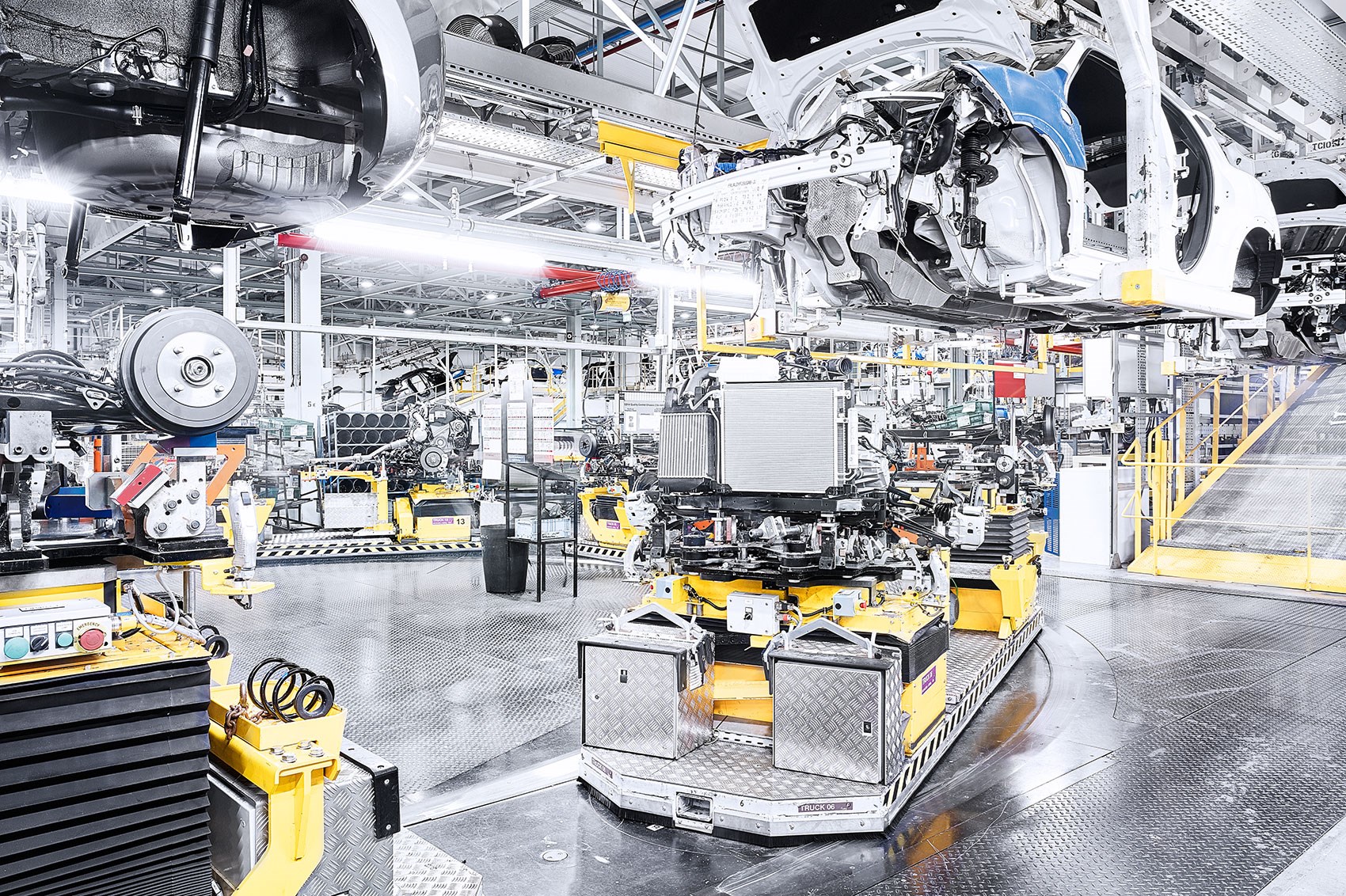

the “Nissan Production Way” (NPW) is a manufacturing and production philosophy developed by Nissan Motor Company

Business Need: Bringing Synchronicity to all Departments.

Renault–Nissan–Mitsubishi Alliance is a strategic partnership between automobile manufacturers Renault, Nissan, and Mitsubishi, which together sell more than one in 10 cars worldwide. The companies have nearly 450,000 employees and control nine major brands: Nissan, Renault, Infiniti, Renault Samsung Motors, Dacia, Datsun, Venucia, Lada and Mitsubishi. The car group sold 8.3 million cars worldwide in 2013, behind Toyota, General Motors, and Volkswagen for total volume.

Douki Seisan feeds into the NPW by:

Foundation of Lean Manufacturing: The Nissan Production Way is grounded in the principles of lean manufacturing, aiming to eliminate waste, optimize efficiency, and enhance overall productivity.

Continuous Improvement (Kaizen): NPW encourages a culture of continuous improvement where all employees are involved in identifying and implementing small, incremental changes to enhance processes and workflows.

Just-In-Time Production: Similar to TPS, NPW emphasizes just-in-time production, aiming to produce goods at the exact time they are needed in the production process, reducing inventory and minimizing storage costs.

Built-In Quality: Quality is a core focus of NPW, promoting the idea that quality should be built into the production process from the beginning rather than inspected afterward. This involves error prevention rather than error detection.

Employee Involvement: NPW emphasizes the involvement of all employees in the improvement process. It values the input and expertise of workers on the production line and encourages teamwork and collaboration.

Standardized Work: The use of standardized work processes is a key element. Standardization helps ensure consistency, quality, and efficiency in production activities.

Visual Management: Visual tools and indicators are used extensively to make information easily accessible to employees on the shop floor. This helps in quick decision-making and problem-solving.

Flexibility and Adaptability: NPW promotes flexibility and adaptability in response to changes in customer demand or unexpected disruptions in the production process.

Our Solution:

We partnered with Nissan to create a curriculum which delivered the concept of synchronized production philosophy. The idea was to improve the company’s productivity and effectiveness and have a global standard production system. So essentially, manufacture according to the real consumer order, thus coordinating all operations and materials.

After the Renault and Nissan alliance took place, Renault embraced the NPW in its plants to produce each other’s automobiles. Renault increased its productivity and decreased its defective parts percentage as a result. We delivered a curriculum which encompassed elements of gamification and self discovery of the APW.

- Designed, translated and deployed across all continents, and in over 12 languages

- After the success of the pilot, the curriculum was deployed across the entire organization – worldwide

- A second curriculum was commissioned for worldwide deployment based on the metrics achieved from the phase 1 curriculum roll-out.

The Results:

Both curriculums were rolled out successfully cross the globe, utilizing 3 different LMS systems and incorporating all 12 languages.